Compressor Automation Made EASY.

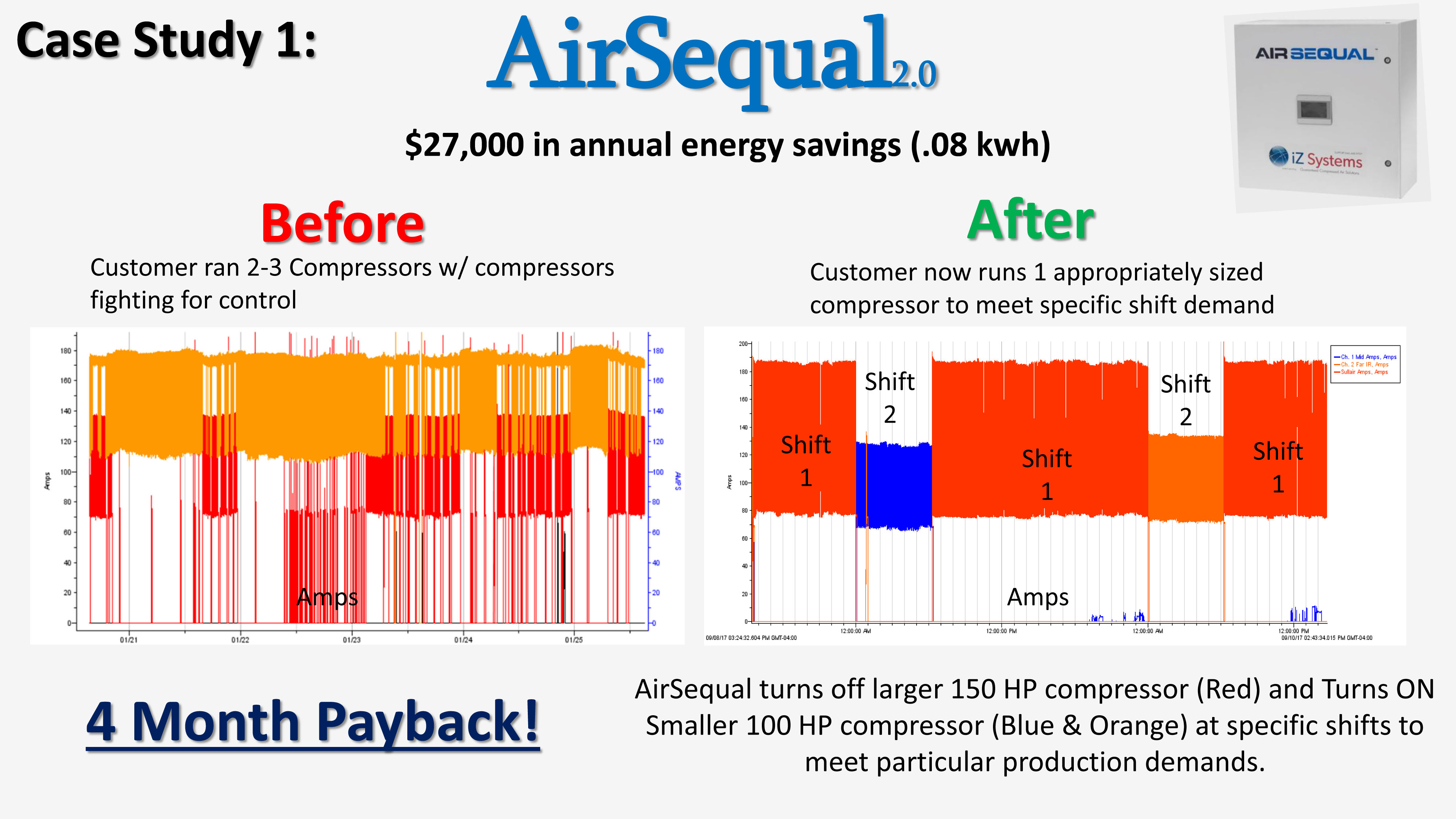

Maintaining pressure within a system that has multiple compressors require a well-defined, pre-engineered solution. AirSequal features the ability to control 2 to 6 rotary screw compressors with a need for basic multiple compressor automation. This automation ssystem orchestartes auto sequence rotation, base/trim control and flow calculations to control starting/stopping and loading/unloading based on a single pressure set point. Save on energy costs, prolong the life of your system and enjoy headache-free operations with AirSequal Multiple Compressor Automation.

FEATURES

- Controls 2 to 6 Rotarey Screws Compressors

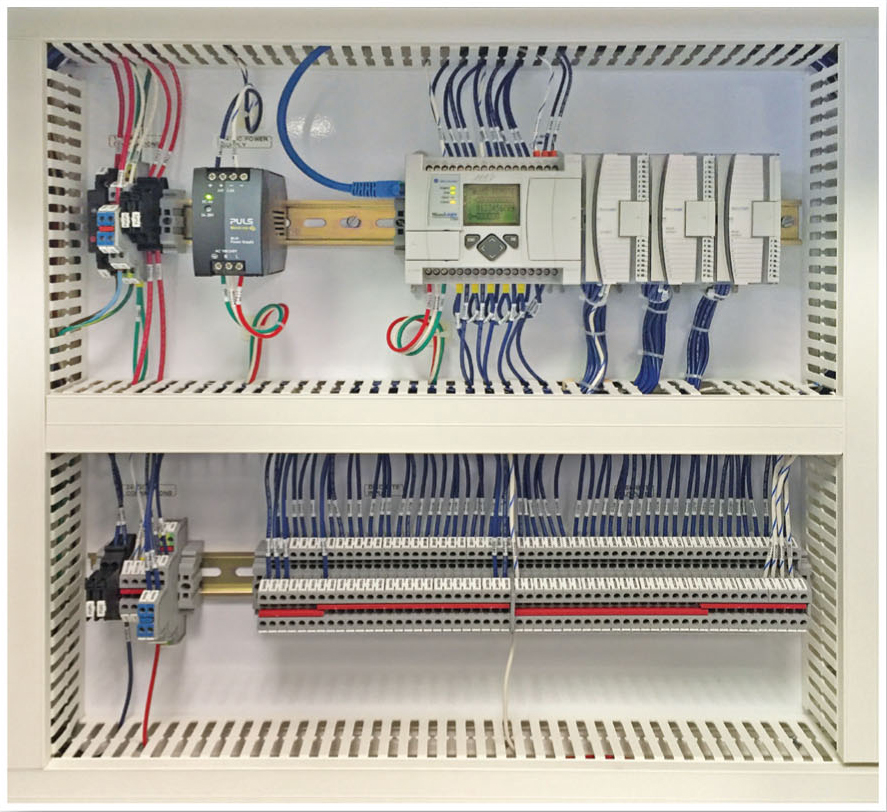

- Allen Bradley MicroLogix1100 PLC

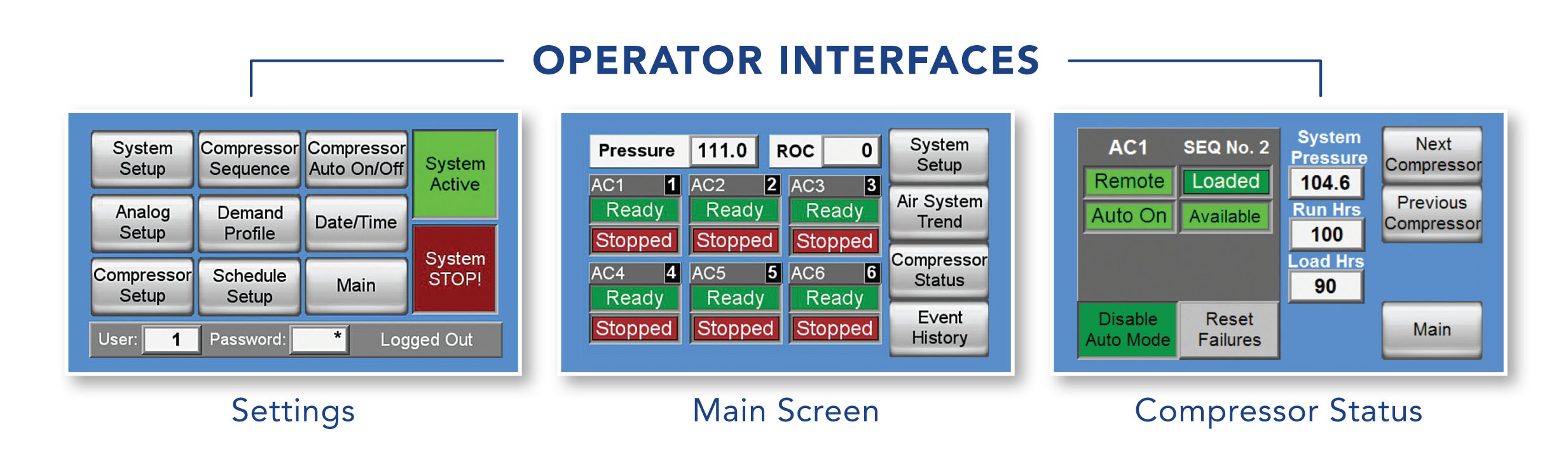

- Simple Color HMI with Standard Terminology Driven Menus

- IIOT Connectivity

- Industry-Proven Compressor Control Logic to Reduce Energy & Provide a More Reliable System

SEQUENCE OF OPERATIONS

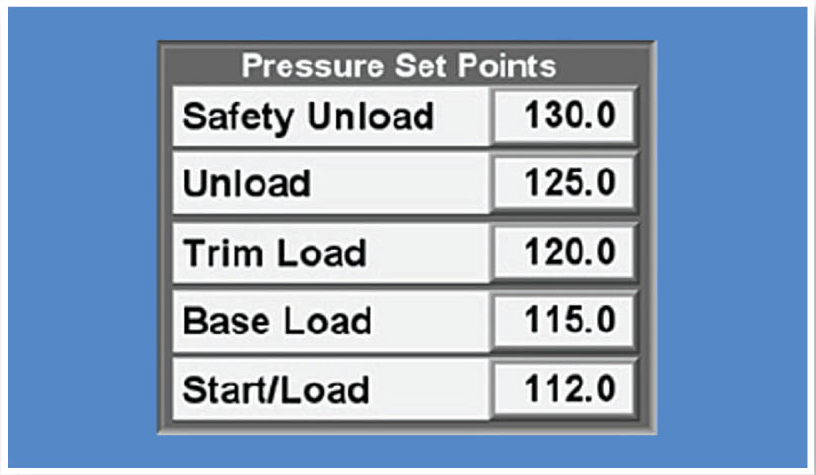

- Manages 2-6 Compressors by starting/stopping and loading/unloading and/or modulating withing the sequence to maintain system pressure

- Use strategically-placed single common pressure signal

- If pressure is less than the Start/Load pressure set point for X seconds, compressor(s) available in the sequence will start and load

- When pressure is greater than the unload pressure set point, compressor(s) will be unloaded

- If a compressor runs unloaded for the predetermined length of time, it will be commanded to stop

- Does not allow multiple compressors to start or stop simultaneously

SMART LOGIC

To prevent loading/unloading more compressors than necessary, the system pressure rate-of-change over time is continuously monitored. If a compressor is started and loaded due to low pressure remains less than the start/load set point -BUT pressure is rising towards the start/load set point - the next compressor in the sequence will NOT start. The same holds true for unloading or removing compressor capcity.

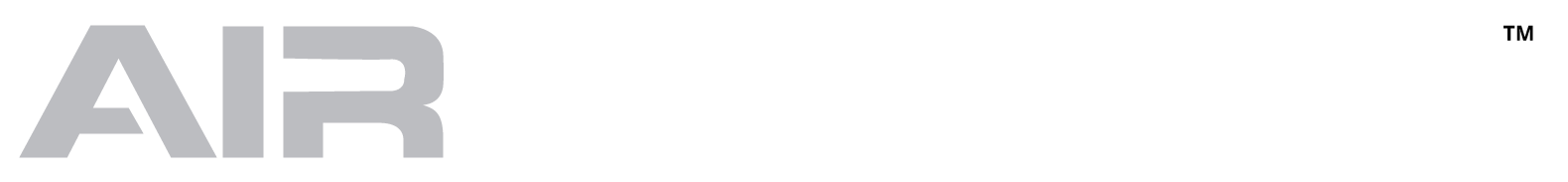

FLOWSEQ

Add an optional flow meter to unlock FlowSeq. As demand changes, the AirSequal will automatically adjust to run the appropriate compressor lineup for maximum efficiency.

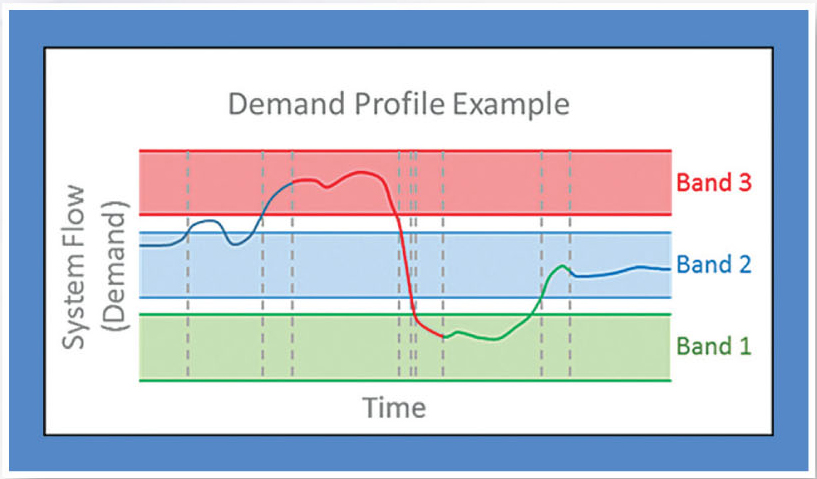

AUTO SEQUENCE ROTATION

Auto rotation functionality is available with the intent of maintaining equal runtime across the compressors. Two auto rotation functions are available: Compressor Runtime Based Rotation and Preset Sequence Based Rotation.

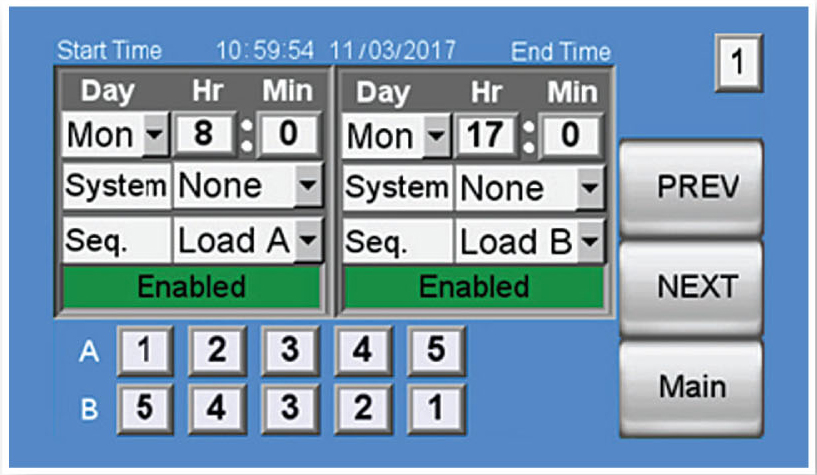

SYSTEM SCHEDULING

Full Calendar based system control. Run the system how and when you want.

- The AirSequal Can Automatically Select a Sequence Based on the Time of Day and Day of the Week to Best Match Production Demand.

- Can Have Up to 7 Different Scenarios

Example: Monday, Wednesday, Friday at 5:00pm the production enters into a low demand period. You can rotate smaller HP units to the lead position and turn off larger HP.

Note: The FlowSeq function would do this automatically, but this method does not require a flow meter.

AUTO SYSTEM START UP & SHUT DOWN

For intermittent compressed air usage, pressurize the system only when it's needed.

- AirSeq Can Start the System at a Particular Time of Day and Day of the Week.

IIOT CLOUD WEB INTERFACE

- Remote Viewing via Web Dashboard

- 90 Day Cloud History Trend

- Alerts and Notifications

- Access via PC or Mobile App

FlowSeq Demand Flow

Auto Sequence Rotation

System Scheduling

System Start/Stop Resume Button

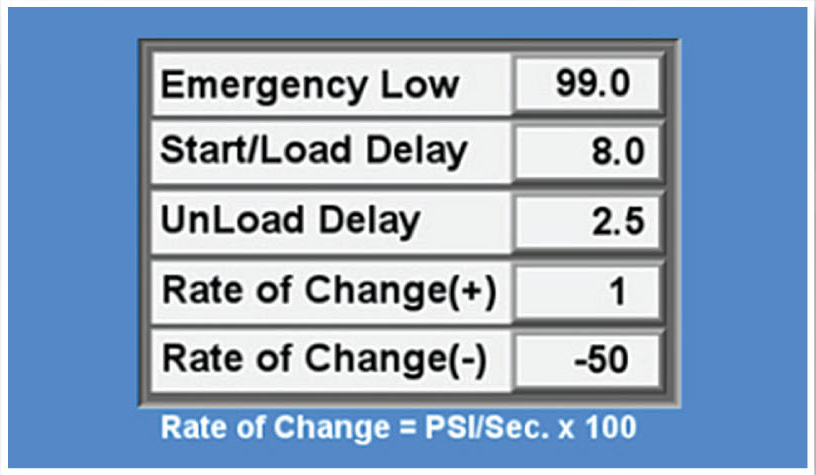

PRESSURE RATE OF CHANGE (ROC)

Rate of Change (+)

The PLC is continuously calculating pressure rate of change over time. This set point is used to prevent falsely starting more compressors than needed when pressure is tracking in the right direction towards the Start/Load set point. If pressure is less than the Start/Load set point, but increasing, the next compressor will not start.

Rate of Change (-)

The PLC is continuously calculating pressure rate of change over time. This set point is used to prevent unloading too many compressors when demand decreases and pressure is tracking in the right direction towards the upload set point. If pressure is greater than the Start/Load set point, but decreasing, the next compressor will not unload.

BASE & TRIM CONTROL

Base/Trim control may be utilized to take advantage of systems containing one or more compressors with modulation capabilities. The number of compressors allowed to simultaneously trim is defined via the operator interface.

AUTO BASE & TRIM CONTROL

When variable capacity compressors are utilized, algorithms are in place to insure all compressors are fully loaded prior to adding additional capacity.

- Prevents Starting or Loading a New Compressor While a Running Compressor is Modulated

- All Compressors will be Fully Loaded Before the AirSequal Turns a New Compressor On

TRUEVENT SYSTEM MONITORING

Don't temporarily demand events control your system. The AirSequal continuously monitors all system conditions to make sure true system events require the AirSequal to deploy a command. This prevents unnecessary and/or erratic compressor starts.

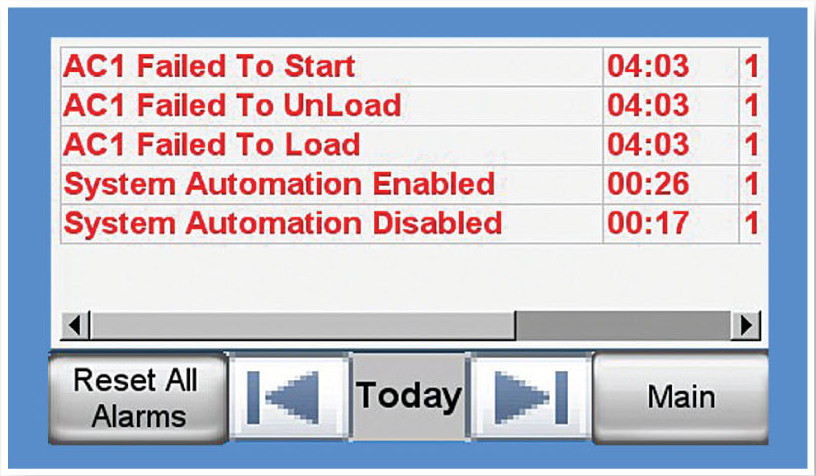

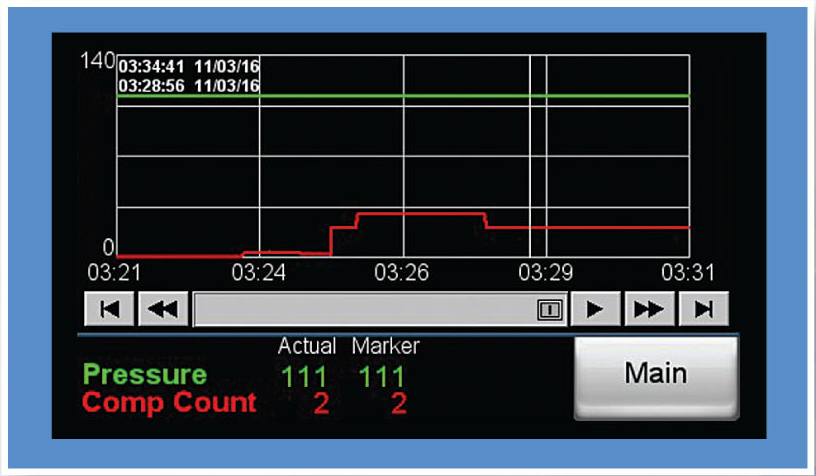

GRAPHICAL TREND & EVENTS HISTORY

- Easily Troubleshoot System Events and Monitor System Performance Over Time

Pressure Rate of Change

Auto Base & Trim Control

Event History

Graphical Trend

Compressor

Automation

Made EASY.

Straight Forward Simple Wiring Interface

A Compresed Air Sysstem with 4 air compressors has:

- 4 Individual Manual Controllers

- 4 Sets of Individual Pressure Set Points

- 4 Process Variables

- 4 Different Capacity Control Systems

- Multiple Horse Power and Capacity Ratings

AirSequal can help all of these different variables run in an efficient and reliable manner.

GET CONTROL FROM A SINGLE VANTAGE POINT WITH AIRSEQUAL

DOWNLOAD THE CATALOG